Division of Plans in Bizkaia

Carbon steels

C45 N

Stabilization is recommended to avoid stresses caused by oxycutting.

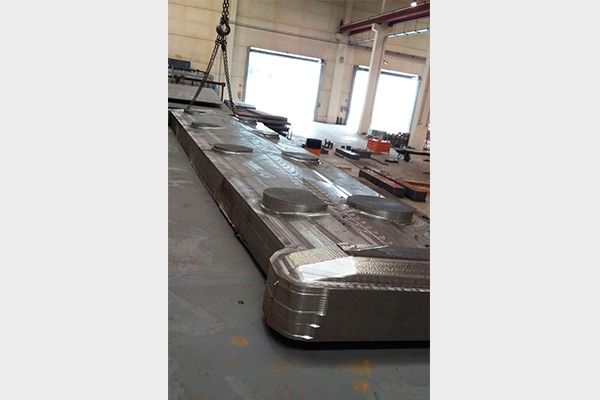

Utilization:

For the construction of molds and mold bases, for large structural parts, support plates, guides, high-strength machine elements, and hydraulic blocks. Agricultural machinery and parts subject to light wear. It is a steel that tempers well and can be used in induction-hardened parts requiring surface hardnesses of around 55 HRC, for example in guides and slides for all types of machine tools.

S355J2 N

Weldable with all types of systems. It is an ideal sheet for cold forming, both on rolls and press brakes. High quality for all types of machining.

Utilization:

For the construction of superstructures, underground mines, bridge construction, hydraulic works, tank construction, machinery, and in general all types of parts requiring a strength between 52 and 62 kg/mm2.

High wear resistance steels

These are high-strength, alloyed, quenched, and tempered wear-resistant steels, ideal for all types of applications requiring high wear resistance, such as industrial tools and machinery.

AT 13% Mn

This is a wear-resistant austenitic Mn steel. It is supplied in an austenitic or hypertempered state, heated to over 1000°C and rapidly quenched in water. This results in an austenitic structure with a strength of approximately 100 Hg/mm2, with good toughness and elongation. It undergoes a self-hardening process on its surface due to friction or impact, a property that gives it great wear resistance.

Utilization:

Shot blasting machines and their spare parts, hammers, jaws, cover plates in mills and crushers, hammers in the cement, ceramics, and mining industries, railway switches, wear plates, electromagnet constructions.

HB-280

HB-280

This is a quenched and tempered wear-resistant steel characterized by its resistance to abrasion and impact. Its high mechanical strength, good toughness, and excellent weldability make it one of the most versatile wear-resistant steels in terms of applications.

Utilization:

For all applications subject to moderate wear caused by impacts or continuous friction caused by hard particles such as stones, gravel, sand, minerals, ferroalloys.

HB-400

HB-400

It is a tempered and annealed alloyed wear-resistant steel characterized by its resistance to abrasion and impact, as well as its high mechanical strength, good formability, and excellent weldability, making this steel the most widely used for all types of applications.

Use:

For all applications subject to high wear caused by violent impacts or continuous and extreme friction caused by hard particles such as stones, gravel, sand, minerals, ferroalloys, coal, dust, etc.

HB-500

HB-500

This is a tempered, alloyed, and annealed wear-resistant steel characterized by its extreme resistance to abrasion and impact. Its high mechanical strength and good weldability make it optimal for extreme situations involving high stresses, impacts, and severe abrasions.

Use:

For all applications subject to high wear caused by violent impacts or continuous and extreme friction caused by hard particles such as stones, gravel, sand, minerals, ferroalloys, coal, dust, etc.

High tensile strength steels

It is a high-yield steel, quenched and tempered, characterized by a guaranteed yield strength of 700 or 890 Nw/mm2 accompanied by high mechanical strength and good toughness, making it ideal for all types of constructions subject to high static or dynamic mechanical stresses.

AU-690

It is a high-yield steel, quenched and tempered, characterized by its guaranteed yield strength of 700 N/mm2 accompanied by high mechanical resistance and good toughness, making it ideal for all types of constructions subject to high static or dynamic mechanical stresses.

Use:

Due to its high hardness and elastic limit, its use is recommended in machines or welded constructions subject to high mechanical stresses that can be of either static or dynamic origin.

Construction of hangars, ventilators, cyclones, and heavy-duty turbines, mobile crane components, chassis, telescopic booms, backhoe arms, and wheel loaders, joining elements subject to combined forces, bridge components, and lightening of metal structures by reducing dead weight.

AU-890

It is a fine-grained, high-yield steel, quenched and tempered, characterized by its guaranteed yield strength of 890 N/mm2, accompanied by high mechanical strength and good toughness, making it ideal for all types of construction subject to great static and dynamic stresses.

Utilization:

Due to its great resistance and high elastic limit, its use is recommended in machines or welded constructions subject to high mechanical stresses that can be of either static or dynamic origin.

The interest in high-strength steels is particularly important given that not only the production cost, but also the operating and productivity costs of a construction are affected by the mechanical characteristics of the material.

The profitability of the steels described has been particularly demonstrated in the manufacture and repair of mobile and fixed cranes, hoisting machines, earthmoving machines and heavy vehicles, rippers and complete shafts for bulldozers, hooks for handling large blocks in quarries or ports, large dumpers, and heavy industrial fans. For all types of earthmoving and public works machinery.

Tool and tool steels

Ideal steels for the manufacture of tools and equipment for professional use.

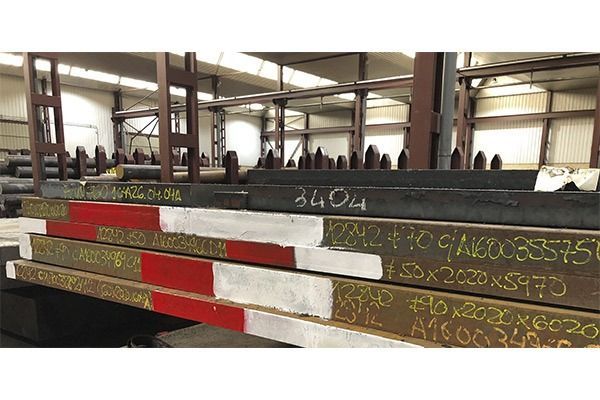

1.2312

1. Chemical composition (see technical data sheet)

2. Application: Molds for highly stressed plastics, mold inserts with high hardness and subject to abrasion stress. Cutting tools of all types, e.g., dies for cutting sheet metal up to 6 mm thick and plastics, threading tools. Wear strips.

3. Delivery condition: Annealed to a maximum of 230 HB≥775 N/mm2. For large molds, it is recommended not to quench and temper until the pre-roughing has been completed.

4. Steel type (see technical data sheet). Notes on tempering: Thicker steels are tempered at 800-820°C, and thicknesses up to 50 mm can be fully tempered. Hot-dip tempering should only be used for thicknesses up to 35 mm.

5. Tempering diagram: Average values for test pieces measuring Ø 20 x 50 mm in length, tempered at 800 ºC in oil. N/mm2 and HB, converted from HRC in each case.6. Physical properties (see technical data sheet).

1.2379/F-521

Applications

High-performance cutting steel. High hardness and wear resistance, excellent toughness, very resistant to pressure, as it deforms little, and nitridable after special treatment. Very suitable for cutting austenitic steels: circular knives and shears. Tools for cold drawing, complicated and break-prone cuts, threaded rollers and die bearings, dies and taps, milling cutters, broaches, etc.

1.2842/F-522

1. Chemical composition (see technical data sheet)

2. Application: Molds for highly stressed plastics, mold inserts with high hardness and subject to abrasion. Cutting tools of all kinds, e.g., dies for cutting sheet metal up to 6 mm thick and plastics, threading tools. Wear strips.

3. Delivery condition: Annealed to a maximum of 230 HB≥775 N/mm2. For large molds, it is recommended not to quench and temper until the pre-roughing has been completed.

4. Steel type (see technical data sheet). Notes on tempering: Thicker sections are tempered at 800-820°C, and thicknesses up to 50 mm can be fully tempered. Hot-dip tempering should only be used for thicknesses up to 35 mm.

5. Tempering diagram: Average values for test pieces measuring Ø 20 x 50 mm in length, tempered at 800 ºC in oil. N/mm2 and HB, converted from HRC in each case.

6. Physical properties (see technical sheet).

C45 N

Stabilization is recommended to avoid stresses caused by oxycutting.

Utilization:

For the construction of molds and mold bases, for large structural parts, support plates, guides, high-strength machine elements, and hydraulic blocks. Agricultural machinery and parts subject to light wear. It is a steel that tempers well and can be used in induction-hardened parts requiring surface hardnesses of around 55 HRC, for example in guides and slides for all types of machine tools.

TX-33

Applications

This is a new steel supplied quenched and tempered. It has high impact toughness and very low residual stresses, providing good dimensional stability. Despite its hardness of 35 HRC, it is easy to machine. It has high resistance to high temperatures and is suitable for dies and molding tools for plastic and rubber, and for die casting, as well as for bending and forming tools for sheet metal. It is suitable for machine components, wear parts, guide rails, high-temperature applications, etc.

TX-44

Applications

TX-44 tool steel. This is a new steel that is available quenched and tempered. It has unmatched impact toughness and very low residual stresses, providing good dimensional stability. Despite its hardness of 45 HRC, it is easy to machine. It has high resistance to high temperatures and is suitable for both dies and molding tools for plastic and rubber, die casting, and sheet metal bending and forming tools. It is ideal for machine components, wear parts, guide rails, high-temperature applications, and more.

Steels for medium and high temperatures

Steels especially suitable for processing at medium and high temperatures.

13CrMo44

They are suitable for all types of resistance butt welding according to DIN 8528, Part 1. If the material has been flame-cut, stabilization is recommended to avoid stresses caused by flame cutting in the areas affected by the cut.

Utilization:

They are preferably used for steam boiler installations, large pressure vessels and construction parts with similar characteristics.