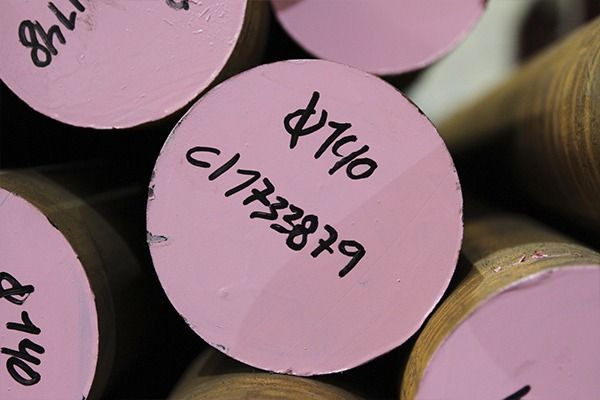

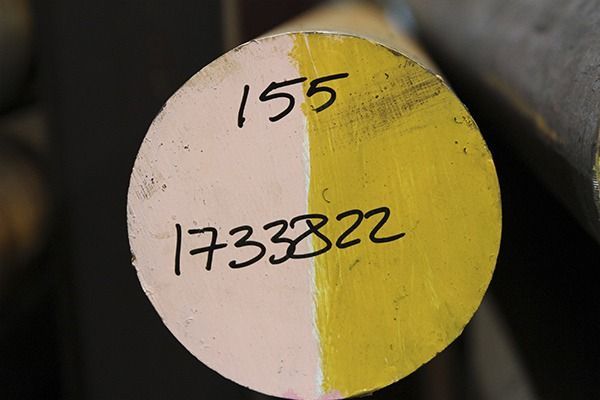

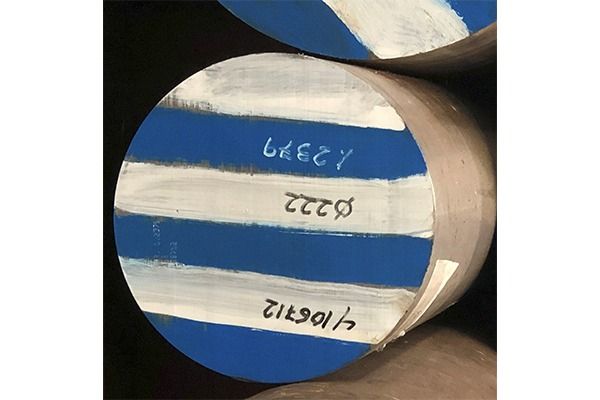

Division of rounds in Bizkaia

Carbon steels

Carbon steels for multiple uses, with different alloys that allow for a wide range of applications, from machinery to tools.

F-1

Applications

A steel with good weldability due to its low carbon content. It can be used as case-hardening steel for heavily drawn parts, for lightly loaded machinery components requiring high toughness, and for low-strength parts that must undergo cold deformation: screws, nails, hardware, etc.

F-112

It supports cold deformation, stamping, bending, etc. It is weldable.

1. Use: Machinery components requiring low loads. Parts with medium strength and good toughness.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-113

It is hardenable and can be welded by the resistance welding method.

1. Use: Machinery elements that require.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-114

It tempers well, but care must be taken to prevent deformation. It can be heat-treated to improve its mechanical properties. Standardized for light-duty parts.

1. Use: Machinery parts and elements that require good strength, such as shafts, sleeves, stamped parts, tie rods, etc.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-115

It tempers well in oil for small amounts; and in water for large amounts.

1. Use: Axles, transmissions, etc. Regularly loaded parts with moderate thicknesses. Used in the manufacture of agricultural tools.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

S355J2/S355J0 (ST52.3)

Room-temperature tensile strength and pull-out limit, perfect for machining. It is suitable for resistance welding and gas pressure welding due to its fairly low carbon equivalent. It is ideal for cold forming when normalized.

1. Use: Superstructures, hydraulic works, machine building, bridge construction, tanks.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

High-strength alloy steels

These are high-strength alloy steels ideal for tooling and automotive parts.

34CrNiMo6

Applications and components that may be subjected to high or low temperatures and that consistently require high stresses in the marine, energy, machine tool, and railway sectors (very good hardenability). It is generally used treated with strengths between 1000 and 1200 MPa. High creep resistance and very stable mechanical properties under all temperature conditions. For transmission shafts, crankshafts, cylinder liners, etc.

F-1252

It accepts surface tempering well.

1. Use: For the manufacture of medium-strength parts, machine and engine parts, of not very large thicknesses, which must have good resistance and high toughness, crankshafts, axles, etc.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-1272

High creep resistance. High hardenability.

1. Use: For high-strength and high-responsibility parts, crankshafts, axles, connecting rods, etc. For parts subject to bending, torsion, impact, etc. Artillery pieces.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

Case hardening steels

This is a case-hardening alloy steel, easy to machine, and offers the potential to achieve a very hard surface layer, combined with good core strength. It presents no problems when welding or flame-cutting due to its low carbon content. However, in some cases, and for thick combined thicknesses, slight preheating is recommended.

17CrNiMo6/18CrNiMo7-6

High hardenability. For cemented parts with core strengths of up to 150 kg/mm2.

1. Use: For the manufacture of large, cemented parts with high strength and surface hardness. These are used for heavy-duty engine and machine parts.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-1522

Good machinability, but prone to deformation due to its low hardenability.

1. Use: For the manufacture of small cemented parts that require little responsibility and where high core toughness is not required.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-1540

For cemented parts with a core strength of 85-125 Kg/mm2.

1. Use: For the manufacture of parts with high surface hardness, medium strength, and high core toughness. Automotive parts, gears, cams, etc.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-1550

For cemented parts with a core strength of 75-130 Kg/mm2.

1. Use: For workpieces with high surface hardness and medium strength. Gears, cams, crowns, and general workpieces that must withstand high friction.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

F-158 Mo

For cemented parts with core strengths of up to 90-140 kg/mm2. It can be preheated and welded.

1. Use: For medium-thickness workpieces subjected to shear and impact stresses requiring surface hardness and core toughness. For gears of any type.

2. Supply status (see technical sheet).

3. Average chemical composition in % (see technical data sheet).

Tool steels

1.2379 / F-521

Applications

High-performance cutting steel. High hardness and wear resistance, excellent toughness, very resistant to pressure as it deforms little, and nitridable after special treatment. Very suitable for cutting austenitic steels: circular knives and shears. Tools for cold drawing, complicated and break-prone cuts, threaded rollers and die bearings, dies and taps, milling cutters, broaches, etc. Non-deformable steels for cold working.

1.2842 / F-522

Applications

Cutting steel. Easily machinable, good cutting performance, good toughness, low distortion, and simple heat treatment. Stamping and cutting tools of all types: taps and dies, drills, gauges, measuring tools, thread-cutting irons, molds for plastics and rubber, stamping dies, etc.

TX-33

Applications

This is a new steel supplied quenched and tempered. It has high impact toughness and very low residual stresses, providing good dimensional stability. Despite its hardness of 35 HRC, it is easy to machine. It has high resistance to high temperatures and is suitable for dies and molding tools for plastic and rubber, and for die casting, as well as for bending and forming tools for sheet metal. It is suitable for machine components, wear parts, guide rails, high-temperature applications, etc.

TX-44

Applications

TX-44 tool steel. This is a new steel that is available quenched and tempered. It has unmatched impact toughness and very low residual stresses, providing good dimensional stability. Despite its hardness of 45 HRC, it is easy to machine. It has high resistance to high temperatures and is suitable for both dies and molding tools for plastic and rubber, die casting, and sheet metal bending and forming tools. It is ideal for machine components, wear parts, guide rails, high-temperature applications, and more.