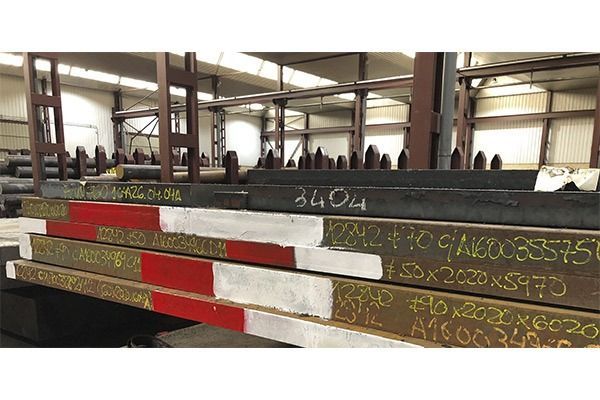

Tool and tool steels

Ideal steels for the manufacture of tools and equipment for professional use.

1.2312

1. Chemical composition (see technical data sheet)

2. Application: Molds for highly stressed plastics, mold inserts with high hardness and subject to abrasion stress. Cutting tools of all types, e.g., dies for cutting sheet metal up to 6 mm thick and plastics, threading tools. Wear strips.

3. Delivery condition: Annealed to a maximum of 230 HB≥775 N/mm2. For large molds, it is recommended not to quench and temper until the pre-roughing has been completed.

4. Steel type (see technical data sheet). Notes on tempering: Thicker steels are tempered at 800-820°C, and thicknesses up to 50 mm can be fully tempered. Hot-dip tempering should only be used for thicknesses up to 35 mm.

5. Tempering diagram: Average values for test pieces measuring Ø 20 x 50 mm in length, tempered at 800 ºC in oil. N/mm2 and HB, converted from HRC in each case.6. Physical properties (see technical data sheet).

1.2379/F-521

Applications

High-performance cutting steel. High hardness and wear resistance, excellent toughness, very resistant to pressure, as it deforms little, and nitridable after special treatment. Very suitable for cutting austenitic steels: circular knives and shears. Tools for cold drawing, complicated and break-prone cuts, threaded rollers and die bearings, dies and taps, milling cutters, broaches, etc.

1.2842/F-522

1. Chemical composition (see technical data sheet)

2. Application: Molds for highly stressed plastics, mold inserts with high hardness and subject to abrasion. Cutting tools of all kinds, e.g., dies for cutting sheet metal up to 6 mm thick and plastics, threading tools. Wear strips.

3. Delivery condition: Annealed to a maximum of 230 HB≥775 N/mm2. For large molds, it is recommended not to quench and temper until the pre-roughing has been completed.

4. Steel type (see technical data sheet). Notes on tempering: Thicker sections are tempered at 800-820°C, and thicknesses up to 50 mm can be fully tempered. Hot-dip tempering should only be used for thicknesses up to 35 mm.

5. Tempering diagram: Average values for test pieces measuring Ø 20 x 50 mm in length, tempered at 800 ºC in oil. N/mm2 and HB, converted from HRC in each case.

6. Physical properties (see technical sheet).

C45 N

Stabilization is recommended to avoid stresses caused by oxycutting.

Utilization:

For the construction of molds and mold bases, for large structural parts, support plates, guides, high-strength machine elements, and hydraulic blocks. Agricultural machinery and parts subject to light wear. It is a steel that tempers well and can be used in induction-hardened parts requiring surface hardnesses of around 55 HRC, for example in guides and slides for all types of machine tools.

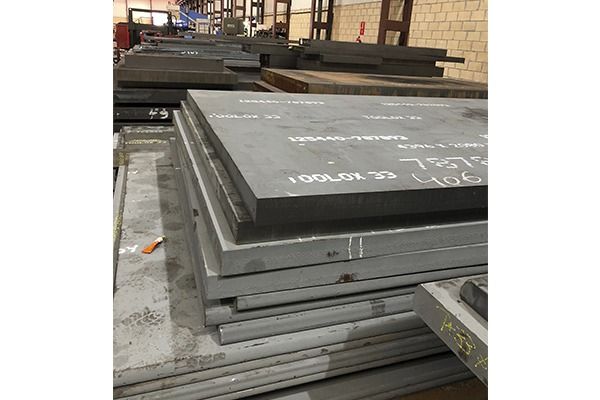

TX-33

Applications

This is a new steel supplied quenched and tempered. It has high impact toughness and very low residual stresses, providing good dimensional stability. Despite its hardness of 35 HRC, it is easy to machine. It has high resistance to high temperatures and is suitable for dies and molding tools for plastic and rubber, and for die casting, as well as for bending and forming tools for sheet metal. It is suitable for machine components, wear parts, guide rails, high-temperature applications, etc.

TX-44

Applications

TX-44 tool steel. This is a new steel that is available quenched and tempered. It has unmatched impact toughness and very low residual stresses, providing good dimensional stability. Despite its hardness of 45 HRC, it is easy to machine. It has high resistance to high temperatures and is suitable for both dies and molding tools for plastic and rubber, die casting, and sheet metal bending and forming tools. It is ideal for machine components, wear parts, guide rails, high-temperature applications, and more.